There is no specific time to replace your static rigging, but regular checks will help you know when to replace a particular wire rope.At the end of the season, a thorough check will give you time to make changes over the winter period, while at the beginning of the season, a quick check of safety pins, fork shafts, etc., will let you make sure your rigging is secure.

Steel suffers fatigue over time, as your rigging is repeatedly stressed (changes of tack, gusts of wind, jolts due to heavy seas, etc.).

So keep an eye on it!

fork shafts and safety pins

cracks in the swaged parts of the terminals (threaded / ½ ball / tee / fork)

the part of the cable entering the swaged terminals

damaged cables

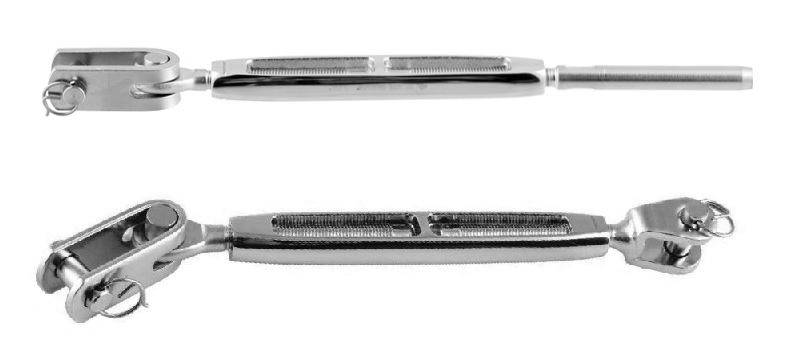

damaged turnbuckles

If during an inspection you find defects on a shroud, then that should prompt you to inspect your entire rigging, and perhaps discover other problems.

replace the cable part A

replace the entire shroud B

or replace the parts

The answer depends on the damage.

If the swage is cracked or the wire rope frayed and the rigging screw is in good condition, then you can replace the wire rope only (A).

If the damage is to a swaged part or if it is located on the swage, then you can cut off the damaged end and replace it with a manual part (Swageless of the Norseman type) with a very long stem.

For DIY enthusiasts, this is a simple operation. Furthermore, for frequent travellers, it is wise to have 1 or 2 well-selected Norseman parts on board (it can be a life-saver in problem situations)!

If only the turnbuckle is damaged, it will definitely be the only part to replace. If the wire rope and any rigging screw parts are damaged, the entire shroud must be replaced. This may concern the shroud or the entire rigging.

Remember that if a wire rope is damaged, then there is a good chance that the whole rigging is tired.

The wise choice would be to replace the main wire ropes (those attached to the masthead). In any case, it is important to find out "how to proceed".

Once you have defined the work to be done, the next step is to know how to do it!

The safest bet!

To do that, it is advisable to remove the mast during the winter or when the boat is not in use. If you remove the shrouds yourself, mark the rigging screw settings clearly and unambiguously, send everything to the rigger: there is almost no need for you to do any more as the rigger will be able to reproduce them exactly.

Measure the rigging and order it as a spare to replace the old set of wire ropes later. If you measure the rigging and send the dimensions to a rigger to produce it "blind" (trusting your measurements), it involves a lot more knowledge, more measurements to be made on site which can be a problem (see next section: Identify your parts and Measurements).

Swageless type parts make it possible for boat owners to replace their wire ropes themselves. You can replace one shroud at a time, so you don't have to remove the mast (saving money, but not time...).

Things you need to know about your shrouds

the wire rope diameter

the fork shaft diameters, these are sized for the wire rope diameter, but there may be small differences depending on the manufacturer.

different rigging lengths (see Measurements section)

terminal types; eye terminals, T-terminals, etc..

the principles of rigging attachment to the mast and the anchor plate models (ideally, take photos and send them to us)

the rigging screw and thread sizes, as well as the thread direction (right / left pitch).

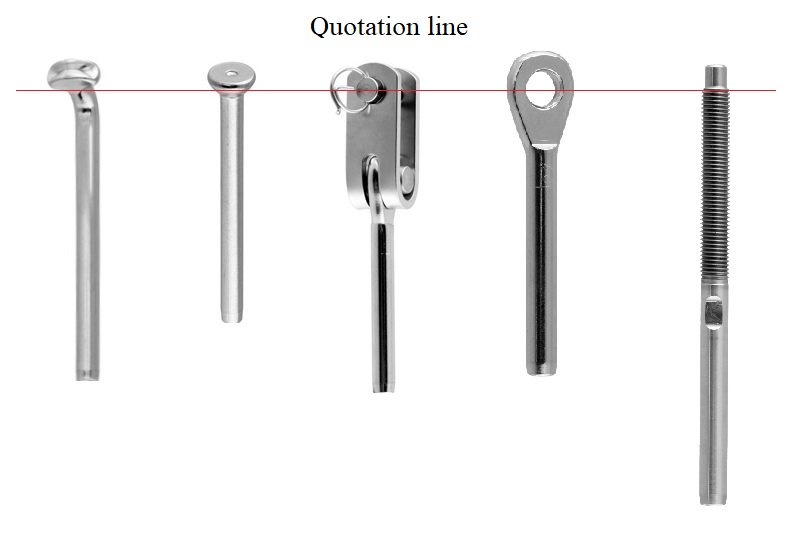

Main types of rigging terminals for sail boats:

eye terminal / toggle fork terminal

half-ball terminal

"Tee" terminal

turnbuckles and threaded terminals

Generally, you will find eye terminals, toggle forks, half-ball and tee terminals "up there".

For those parts, you will need to know the wire rope diameter, and the wire rope attachments (the shaft , attachment and anchor plate sizes).

We can guide you if you need help. Remember to take pictures, it makes the discussions easier.

The turnbuckles with eye terminals and toggle fork terminals are usually found at the bottom.

For those parts you need the wire rope diameter, the fork shaft diameter, the rigging screw diameter (the pitch/thread size), and the direction of the different threads.

NB:

For a given wire rope, the thread used can be of several possible sizes. For example: For a Ø8 mm wire rope, the turnbuckle thread can be either M12 or M14 or 1/2" or 5/8" !!! ....

What dimensions do you need?

Shaft to shaft dimensions, wire rope size, identification of terminal types and termination shaft size are important. Some riggers use the centre of the shaft as the definition of an end point, others use a support point.

To measure a shroud, drive a nail into a suitable surface. Attach the end of the shroud to the nail and then attach a tape measure to the same nail.

Unroll the shroud and the tape measure and pull it taut.

If you are making a brand new shroud, you will need to measure the old one as it was set (make sure to mark the setting when you remove it).The new one should be calculated at the setting 2/3 out.

With the turnbuckle 2/3 out, you have enough length to tighten the shroud once the mast is in place. Rigging is calculated to provide an efficient tautening distance.

This 2/3 opening is an industry standard, although some people prefer a half stroke adjustment.