SWAGELESS TERMINALS AND TURNBUCKLES

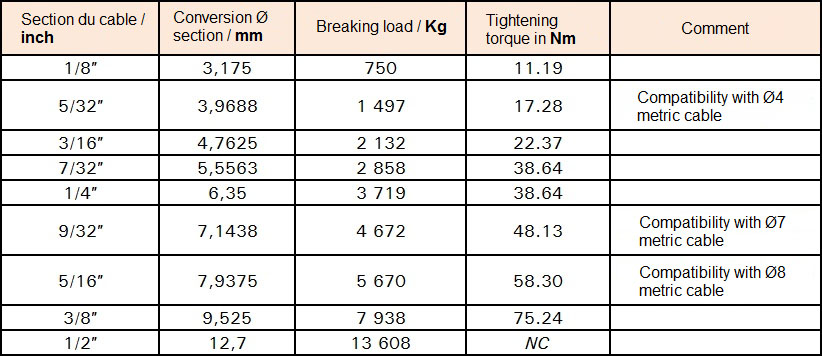

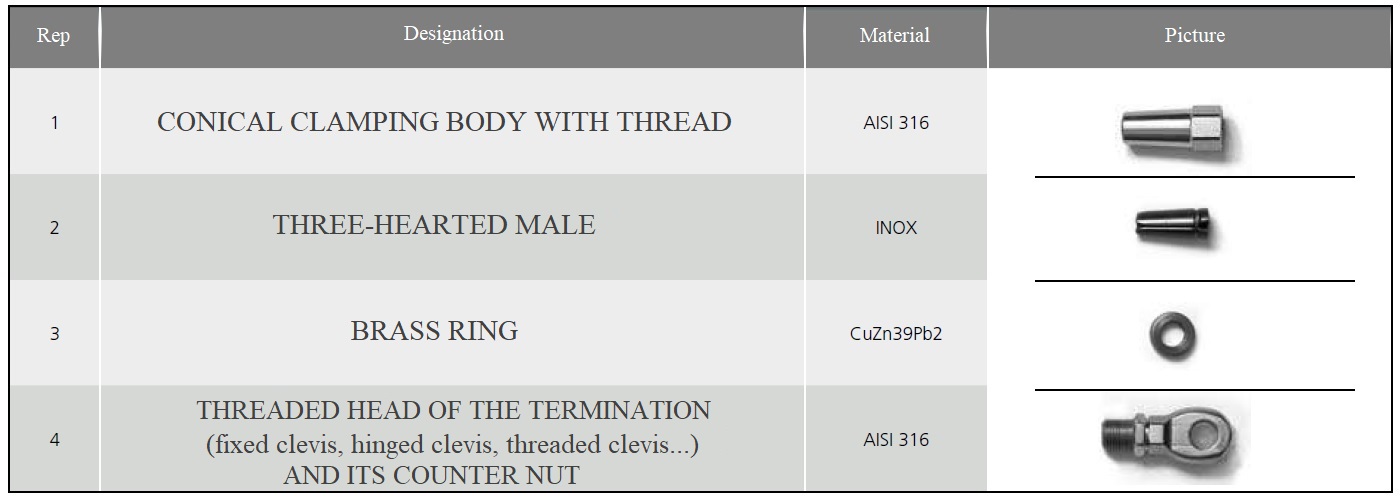

1) Parts list + exploded view of a swageless terminal.

2) Assembly principle.

- Push the conical body 1 onto the cable

- Position jaw 2 evenly on the cable

- Place ring 3 against the jaw 2, taking care to leave at least 5 mm between it and the cable end

- Move body 1 onto jaw 2

- STRONGLY screw on terminal 4 and secure the assembly using the counter nut

3) Recommendations and maintenance.

- You can use our "swageless " manual terminals with construction cables (1*19) , (7*7), (7*19), or Dyform cables.

- Make sure that the cable cross-section matches the terminal dimensions used.

- For extended use in saline or highly polluted environments, regularly check the terminal for damage and/or seal the entire terminal during assembly using a sealant such as SIKAFLEX 221 ® . If the seal is damaged, clean the terminal with fresh water and then treat it with a metal lubricant, and re-apply the sealant.

- When using these terminals, the cable strength is reduced by 0 to 15%, depending on the cable diameter and how rigorous your assembly has been.

- The jaws are single use only and cannot be re-used.

- Users are responsible for checking the correct equipment selection/sizing and its proper assembly.

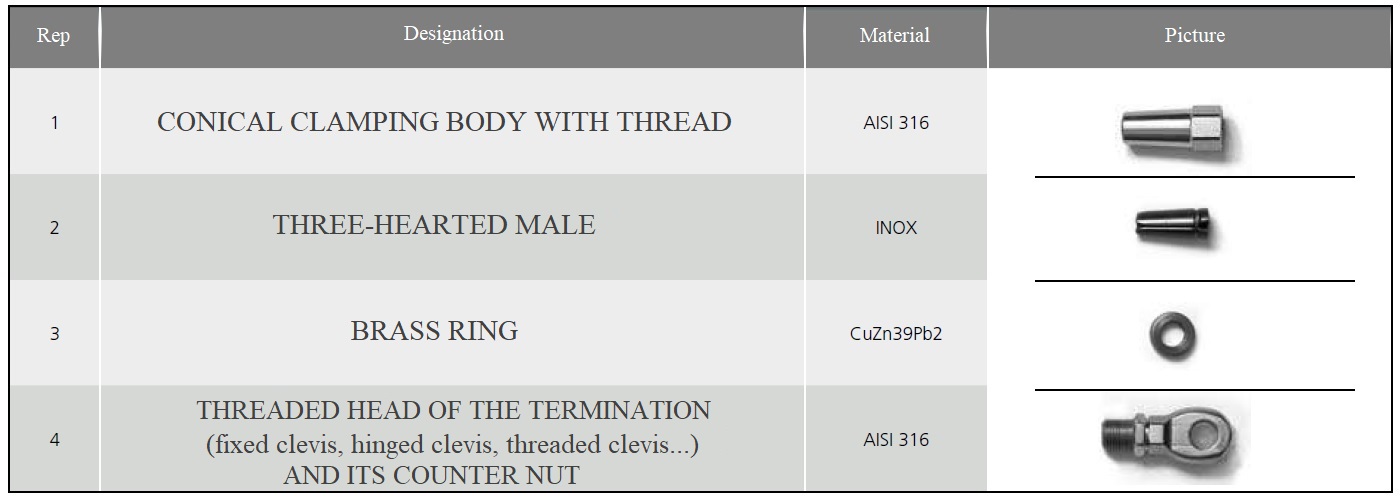

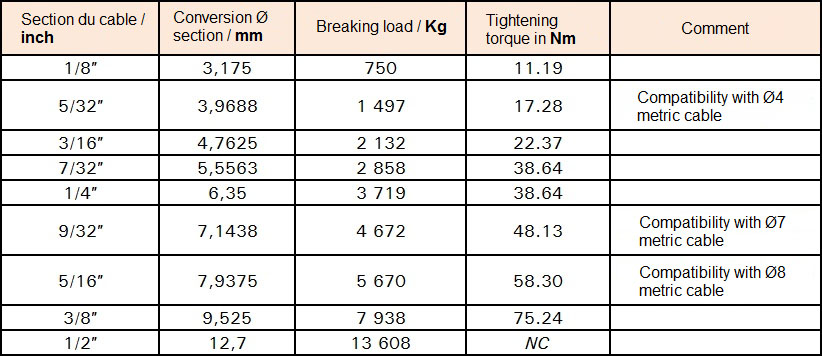

4) Table of "Swageless" terminal technical specifications

| Cable cross-section in mm |

Breaking load in Kg |

Tightening torque in N.m |

| 3 |

700 |

11 |

| 4 |

1500 |

17 |

| 5 |

2000 |

22 |

| 6 |

2900 |

38 |

| 7 |

4000 |

48 |

| 8 |

5200 |

58 |

| 10 |

8200 |

75 |

| 12 |

11800 |

NC |

| 14 |

17000 |

NC |

| 16 |

23000 |

NC |

This range of parts is manufactured in an ISO9001 factory and has been entered on the LLOYD'S REGISTER.