The swaging of a terminalor a turnbuckle* on a cable consists in pressing a defined part of the terminal lengthways, and requires a specific machine.

Strict compliance with the shrinking values (diameter and length) guarantees good swage strength.

INOX SYSTEM produces your swaged cables directly in its workshops using hydro-electric roller machines that meet European standards, and we guarantee the result.

The production of a swaged cable requires precise measurements. The main assemblies presented in KIT & MAIN ASSEMBLIES indicate the information you need to send us. Feel free to contact the INOX SYSTEM technicians to help you with your measurements.

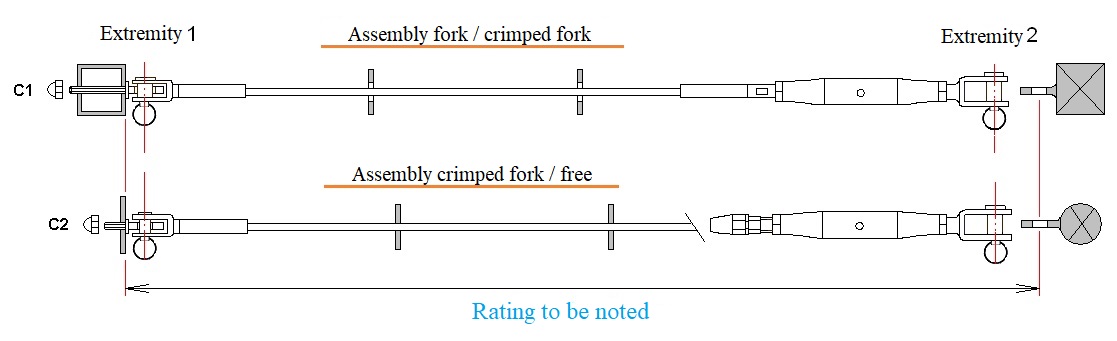

Assembly example:

When installing a guardrail type cable that is swaged at both ends, intermediate posts or uprights need to be prepared to pass the threaded terminal.

(For turnbuckles, the swaged terminal body should be completely unscrewed)

Below is a summary table of the maximum diameter of each threaded terminal, as well as details of the threading.

| RIGHT / LEFT ref | Cable Ø | Threading | L | KW | Post drill hole Ø |

| IS72025 / IS72125 | 2 | M5 | 42.0 | 4.5 | 6.0 |

| IS72055 / IS72155 | 2.5 | M5 | 42.0 | 4.5 | 6.0 |

| IS72036 / IS72136 | 3 | M6 | 48.0 | 5.0 | 7.0 |

| IS72046 / IS72146 | 4 | M6 | 57.0 | 6.0 | 8.0 |

| IS72048 / IS72148 | 4 | M8 | 57.0 | 6.0 | 8.0 |

| IS72058 / IS72158 | 5 | M8 | 57.0 | 7.0 | 9.5 |

| IS72050 / IS72150 | 5 | M10 | 63.5 | 7.0 | 10.5 |

| IS72060 / IS72160 | 6 | M10 | 63.5 | 11.0 | 13.0 |

| IS72062 / IS72162 | 6 | M12 | 80.0 | 11.0 | 13.5 |

| IS72072 / IS72172 | 7 | M12 | 88.0 | 12.0 | 15.0 |

| IS72074 / IS72174 | 7 | M14 | 88.0 | 12.0 | 15.0 |

| IS72082 / IS72182 | 8 | M12 | 79.0 | 14.0 | 16.5 |

| IS72084 / IS72184 | 8 | M14 | 88.0 | 14.0 | 17.0 |

| IS72086 / IS72186 | 8 | M16 | 88.0 | 14.0 | 17.0 |

| IS72006 / IS72106 | 10 | M16 | 99.0 | 15.0 | 19.0 |

| IS72000 / IS72100 | 10 | M20 | 121.0 | 15.0 | 19.0 |

| IS72020 / IS72120 | 12 | M20 | 120.0 | 17.0 | 21.5 |

| IS72022 / IS72122 | 12 | M20 | 120.0 | 19.0 | 21.0 |

| IS72042 / IS72142 | 14 | M22 | 140.0 | 22.0 | 26.8 |

| IS72026 / IS72126 | 16 | M22 | 140.0 | 25.0 | 28.5 |

| IS72064 / IS72164 | 16 | M24 | 170.0 | 25.0 | NC |

| IS72097 / IS72197 | 19 | M27 | 180.0 | 30.0 | NC |

Some configurations do not allow for accurate measurements, in such cases we recommend you only swage one cable end and plan on fitting a swageless terminal or turnbuckle onthe free cable end.

This type of assembly provides more flexibility in measurements and assembly, but also makes it possible to only drill holes in the intermediate posts or uprights of the cable diameter +0.5mm.

| Cable cross-section in mm | Breaking load in Kg | Tightening torque in N.m |

| 3 | 700 | 11 |

| 4 | 1500 | 17 |

| 5 | 2000 | 22 |

| 6 | 2900 | 38 |

| 7 | 4000 | 48 |

| 8 | 5200 | 58 |

| 10 | 8200 | 75 |

| 12 | 11800 | NC |

| 14 | 17000 | NC |

| 16 | 23000 | NC |

* Glossary:

Turnbuckle = tensioner

Swageless = not swaged using a machine